- Home

- About Us

- Products

- Customize Washer

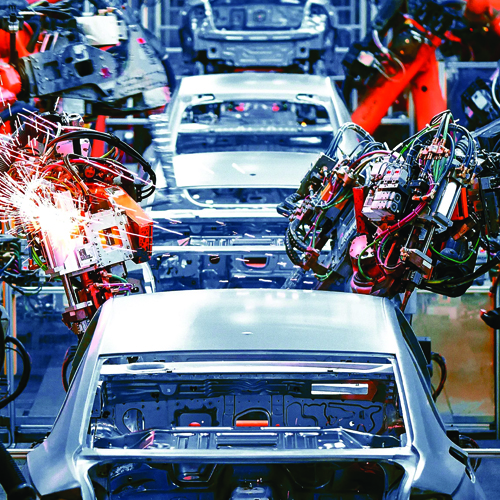

- Automotive Customized Components

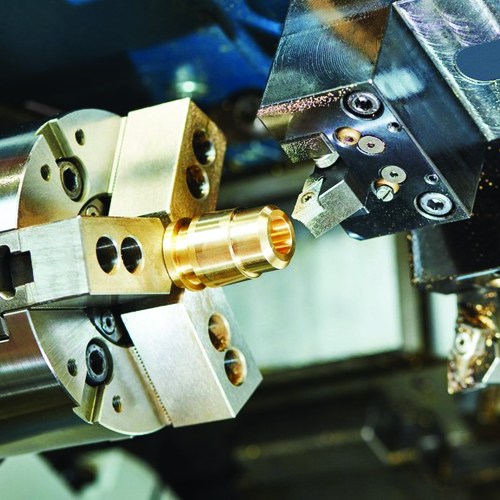

- Brass CNC Turned Components

- Sheet Metal Components

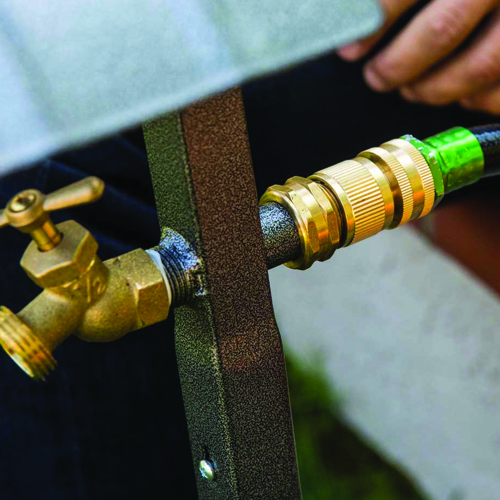

- Brass Hose Fitting Components

- Temprature Sensor Components

- Sanitary Fitting Components

- Customized Product

- Male & Female Components

- Fasteners Components

- Brass Sealing and Meter Screw

- Brass Moulding Insert

- Brass Nut Bolt

- Brass Standoff Screw

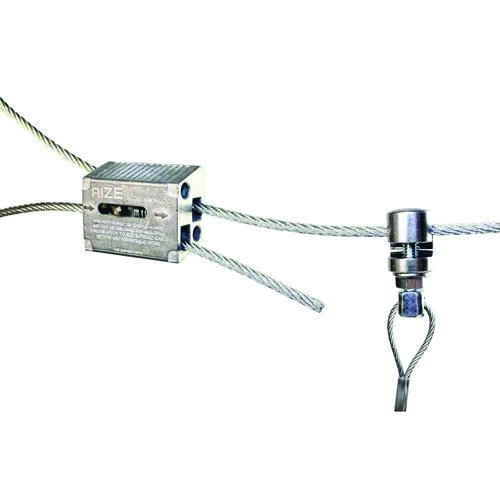

- Cable Glands

- Battery Terminals

- Neutral Terminal Block

- Copper Lugs

- Casting Forging and Components

- EVR Motor Machined Components

- Allen Cap Head Screw

- Busbar

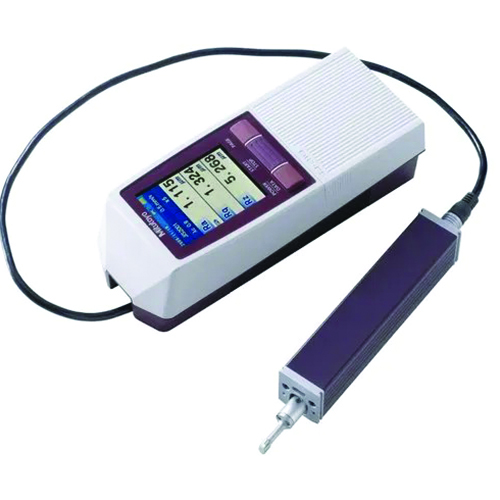

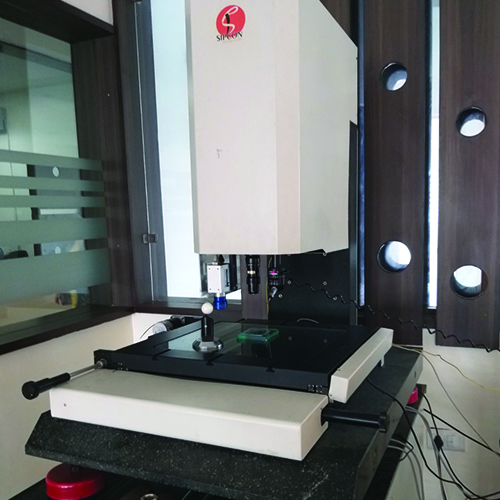

- Quality

- Inquiry

- Contact Us